From shape modification to machining simulation

Tebis: High-performance CAD+CAM System

Tebis AG

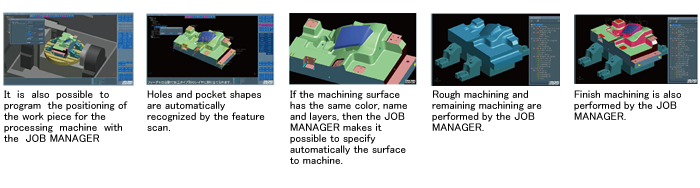

Tebis directly reads CAD data (e.g. CATIA) and from the CAD function that creates and modifies shapes, there is total support in the

manufacturing process; up to the creation of tool paths for processing and processing simulations. This is a die and mold

manufacturing system used by Toyota, Honda, Nissan, Mazda, GM, Ford, Daimler, BMW, Volkswagen and Audi, among others.

Features

- ■Solid models is imported from variety of CAD by a direct interface and a surface model is created. Necessary transformation and editing for the mold creation takes place and then the tool path for NC processing is created. It is also possible to directly feedback the edited model to CATIA V5, for example, and to re-build sold model.

- ■The tool path directly calculated from the mathematical surface formula is created with extremely high-precision at amazement speeds Finally, a mirror surface finish is realized.

- ■Tool paths are created that are suitable for high-speed machining without a drop in processing speeds. Uncut stock is recognized and without creating wasteful tool paths, no uncut portions occur.

- ■All operations are structured and stored. All processing from the rough processing to the finish, is listed as a program (JOB MANAGER) by Automill technology and it is possible to reuse the JOB MANAGER when manufacturing similar shapes.

Tebis program processing that can take place totally automatically or semi-automatically

Control the laser processing machine with CAD data

Tebis Laser: Teaching-less 5-axis Trim Processing

Tebis AG

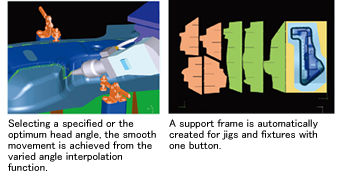

It is possible to produce interference-free, multi-axis laser processing paths, which are

required in the laser machining of prototype models, with interactive simple operations.

At the same time, the operator can perform a variety of simultaneous checks, such as

on the machine head, the variation range in each axis and the operational limit.

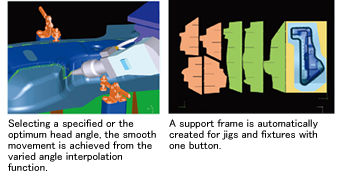

Furthermore, it is possible to directly carry out the support jig design of the panel from

the CAD model and/or the scan data of the actual panel. This has significantly

shortened manufacturing processes that previously took a great deal of time.

Features

- ■Standard shapes (e.g. slots and circles) utilize subroutines in the processing machine controller, so fast and accurate processing is achieved

- ■Operations are totally automatic or step-by-step

- ■A complete interference check is performed that includes the machine head, and the direction of the head axis can be freely specified

Products_Automobiles/Mechanical Equipment

Products_Automobiles/Mechanical Equipment